Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

Plasma surface treatment machine can change the surface properties of the material and make it easier to bond and paint:

Plasma surface treatment machine is used to change the surface properties of various materials to make it easier to bond and paint. Plasma is used to process the parts, so that the plasma surface treatment function can clean and activate the surface and improve its adhesion performance.

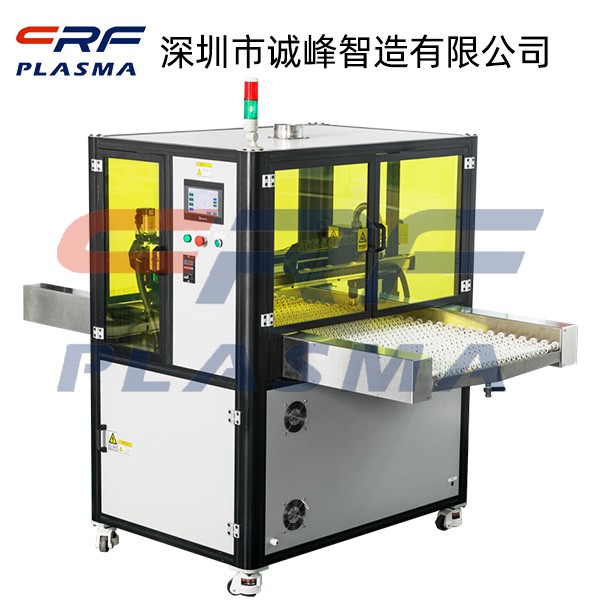

Plasma surface treatment machine

Measuring the surface tension of the material within a certain range is the decisive factor for the adhesion of the liquid to the surface. In order for the liquid to properly bond with the surface of the substrate, the surface tension of the substrate must be greater than 2-10 cm/cm of the liquid surface tension. As the surface tension between the solid phase and the liquid phase increases, the wettability of the solid phase also increases. Many plastic materials have insufficient surface energy for printing and bonding. The main examples are polypropylene and polyethylene. This type of material has many advantages and is a favorite material. However, due to their poor wettability, design options are severely limited. Most materials have the problem of being difficult to bond. The plasma surface treatment machine is applied to the surface treatment of various materials, which can improve various bonding problems.

Combine reactive gas molecules with an electric field to form atmospheric plasma. This plasma surface treatment machine system uses one or more high-voltage electrodes that can charge surrounding gas molecules, resulting in a high ionization field on the target surface. This highly ionized air flow will generate thermal properties that react with the substrate and break the existing hydrogen bonds by introducing oxygen, so that the chemical properties of the surface can be reproduced. The atmospheric plasma (or air plasma) process can cause a strong reaction with the substance, resulting in better wettability, stronger adhesion, micro-cleaning of the surface, and elimination of the possibility of undesirable reverse treatment.

Conventional ceramic processing heads have poor elasticity, high mechanical strength, and high maintenance costs. The nozzles of the plasma surface treatment machine made by Chengfeng Zhizhi are all metal, very durable, and are firmly connected to the transformer through air and high-pressure hoses. The compact design of the processing head and the integrated utility pipe require small space and can be easily integrated on one or more pipelines. It is specially designed for rapid configuration changes and product positioning. It can reduce downtime while providing consistent handling.

From 2MM direct spray to 80MM rotary nozzle, to vacuum plasma surface treatment machine with sealed cavity, it can fully meet the different surface treatment requirements of customers. For example, applications involve thicker materials such as plastic sheets, paper, foam or glass, surface innovation of plastics, metals and textiles, powerful plasma surface treatments, and even plastic sheets and foams.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The effect of the oxidizing gas N2 on the conversion reaction under the action of plasma

more >Study on the removal mechanism of micro-nano particles on silicon surface by plasma cleaning process

more >Research progress on the interaction between plasma and catalyst of plasma radio frequency power supply

more >Plasma surface treatment machine is suitable for cleaning plastic industrial materials that are not resistant to high te

more >AFASAGAR plasma spraying machine processing anti-fingerprint, oil stain and anti-reflective functions

more >Chengfeng Zhizhi surface plasma processing equipment for your wafer silicon photoresist removal examples

more >