|

Name

|

Automatic On-Line AP plasma processing system

|

|

Model

|

CRF-APO-500W-C

|

|

Power supply

|

220V/AC,50/60Hz

|

|

Plasma power

|

2set*600W/25KHz(Option)

|

|

Effective processing height

|

5-15mm

|

|

Processing width

|

50-500mm(Option)

|

|

Processing speed

|

0-5m/min

|

|

Transmission mode

|

Anti-static insulated conveyor belt

|

|

Number of print heads

|

2(Option)

|

|

Working gas

|

Compressed Air(0.4mpa)

|

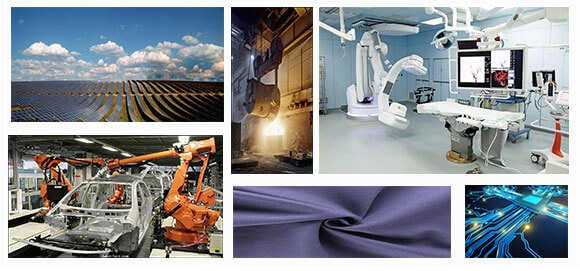

Plasma cleaning machine adhesive technology in the automotive industry

With the development of economy, consumers have higher and higher requirements for the performance of automobiles, such as automobile appearance, operating comfort, reliability, and durability. In order to meet the requirements of consumers, automakers pay more attention to the optimization and improvement of details when producing cars. Everyone knows that cars are assembled from a large number of parts, and the main materials that make up these parts are steel and plastic.

How are these parts assembled together? Perhaps many people thought of screwing and welding for the first time. Some people also thought of riveting.

These are the more common ways to assemble cars. And if you say that the car is also glued together, you may also feel shocked. In fact, the adhesive technology has been widely used in the automotive field. It is not an exaggeration to say that cars are glued together.

Since it is glued, why is it so strong? This is a new type of technology, called plasma cleaning technology, which can enhance the bonding ability, hydrophilicity, cleaning and many other functions of the surface of the object, such as:

1. Plasma increases surface roughness:

When the adhesive infiltrates the surface of the material to be adhered well (contact angle θ<90°), the roughening of the surface is beneficial to increase the degree of infiltration of the adhesive liquid on the surface, increase the density of the contact point between the adhesive and the material to be adhered, and thus help improve the adhesion接 Strength. Conversely, when the adhesive does not infiltrate the material to be adhered (θ>90°), the roughening of the surface is not conducive to the improvement of the bonding strength. To

2. Plasma surface treatment:

Surface treatment before bonding is the key to successful bonding, and its purpose is to obtain a strong and durable joint. Due to the existence of the "weak boundary layer" formed by the oxide layer (such as rust), chrome plating, phosphating layer, release agent, etc. of the adherend, the surface treatment of the adherend will affect the bonding strength. For example, the surface of polyethylene can be treated with hot chromic acid oxidation to improve the bonding strength. When heated to 70-80°C for 1-5 minutes, a good bondable surface will be obtained. This method is suitable for polyethylene plates, thick Wall tube etc. When the polyethylene film is treated with chromic acid, it can only be carried out at room temperature. If it is carried out at the above temperature, the surface treatment of the film will adopt plasma or micro flame treatment. To

When the surface of natural rubber, styrene butadiene rubber, nitrile rubber and chloroprene rubber is treated with concentrated sulfuric acid, it is hoped that the rubber surface will be slightly oxidized. Therefore, the sulfuric acid should be thoroughly washed off in a short time after acid application. Excessive oxidation instead leaves more fragile structures on the rubber surface, which is not conducive to bonding. To

When locally bonding the vulcanized rubber surface, the surface treatment removes the release agent, and it is not advisable to use a large amount of solvent to wash, so as not to prevent the release agent from spreading to the treated surface and hinder bonding. To

For the surface treatment of aluminum and aluminum alloys, it is expected that aluminum oxide crystals will be generated on the aluminum surface, while the naturally oxidized aluminum surface has ten irregular and relatively loose aluminum oxide layers, which is not conducive to bonding. Therefore, the natural aluminum oxide layer needs to be removed. However, excessive oxidation will leave a weak layer in the bonded joint. To

3. Plasma surface etching:

Through the effect of the treatment (gas) body, the etched object will become gaseous and discharged, and the surface of the material can be treated to achieve the effect (effect) of recess etching, which can improve the adhesion and durability between the materials.

4. Plasma surface modification:

Take polytetrafluoroethylene (PTFE) as an example, it cannot be printed or glued without treatment. Plasma treatment can make the surface Zda, and at the same time form an active layer on the surface, so that PTFE can be bonded, printed and other operations.

5. Plasma surface activation (transformation):

Break the molecular bonds on the surface of the material to form new substances and improve adhesion. Mainly used to clean plastic, glass, ceramics and non-polar materials such as polyethylene (PE), polypropylene (PP), polytetrafluoro (PTFE), polyoxymethylene (POM), polyphenylene sulfide (PPS), etc.

6. Plasma surface coating:

In plasma coating, two gases enter the reaction chamber at the same time, and the gases will polymerize in a plasma environment. This application is much more stringent than activation and cleaning requirements. Typical applications are the formation of protective films for fuel containers, scratch-resistant surface coatings, coatings similar to polytetrafluoro (PTFE) materials, and waterproof coatings. (Decompose polymer). Plasma cleaning technology has been used in many fields of industry, and it is believed that the application of this technology will be more extensive in the future.

7. Plasma surface coating

A protective film is formed on the surface of the material to protect the material. The following is a detailed description of the specific use of these characteristics of the plasma cleaning machine in life.

1. Ignition ring

The ignition coil has the power to increase (lift), and the obvious (significant) effect (result) is to increase (lift) the low-to-medium-speed torque when driving; (eliminate) carbon deposits, better protect the engine, and extend the life of the engine; reduce or Eliminate (remove) the resonance of the engine; fuel charge (distribute) combustion, reduce emissions and many other functions. In order for the ignition coil to play its role, its quality, reliability, and service life must meet the standards. However, there are still big problems in the production process of the ignition coil-after the ignition coil frame is poured with epoxy resin, Because the skeleton contains a large amount of volatile oil on the surface of the mold, the bonding between the skeleton and the epoxy resin is not reliable. When the finished product is used, the temperature rises at the moment of ignition, which will generate bubbles in the tiny gaps on the bonding surface, which will damage the ignition. The coil, in serious cases, will explode.

After using plasma treatment, it can not only remove the hardly volatile oil stains on the surface, but also greatly improve the surface activity of the skeleton, that is, it can improve the bonding strength of the skeleton and the epoxy resin, avoid the generation of bubbles, and increase the contact between the enameled wire and the skeleton after winding. Point of welding strength. As a result, the performance of the ignition coil in all aspects of the production process has been significantly (remarkably) improved, and the reliability and service life are improved.

2. Engine oil seal

The engine crankshaft oil seal prevents the engine oil from leaking from the engine and prevents foreign matter from entering the engine. The crankshaft oil seal is one of the engine parts and comes into contact with the engine oil at high temperatures. Therefore, materials with excellent heat resistance and oil resistance are required. High (grade) cars generally use polytetrafluoroethylene material. With the continuous improvement of automobile performance requirements, more and more manufacturers have gradually used this material, and its application prospects are very broad.

3. Other applications in the automotive industry

(1) The instrument panel is treated before the flexible polyurethane coating;

(2) Pre-treatment of control panel bonding;

(3) Pre-treatment of internal PP parts for planting tape;

(4) Treatment of automobile door and window seals;

Many manufacturers have used plasma technology to treat these substrates. Through plasma bombardment, the micro-level activity on the surface of the material is enhanced, which can significantly (significantly) improve the coating effect (fruit). According to experiments, different process parameters need to be selected to treat different materials with a plasma cleaning machine to achieve better activation (chemical) effects (fruits).

Plasma cleaning machine processing can not only improve the bonding quality, but it also provides new process possibilities using low-cost materials. After plasma cleaning machine treatment, the surface of the material obtains new characteristics, so that ordinary materials can obtain the surface processing performance of the original special materials. In addition, the cleaning effect of plasma eliminates the need for solvent cleaning, which is environmentally friendly and saves a lot of cleaning and drying time.