Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

Plasma surface treatment Plasma activation cleaning application and effect detection:

The process of plasma surface treatment includes plasma surface cleaning, plasma surface activation, plasma surface etching, and plasma surface coating. The plasma surface treatment process is widely used in many industries and fields, such as precision electronics, semiconductors, automobile manufacturing, biomedical, new energy, textile printing and dyeing, packaging and printing, etc.

1. Plasma Surface Activation

Taking the improvement of ink adhesion as an example, the surface energy of some polymer materials is relatively low, and it is difficult to bond and combine with the ink. Plasma surface treatment can clean the surface of the polymer material, and can also break the molecular bonds on the surface of the material. It forms a hydrophilic group with stable performance, thereby improving the adhesion of the ink. When the price of the ink sample is high, it can also reduce the use of the ink and reduce the cost. The following is a comparison before and after plasma surface activation treatment. Plasma surface activation is generally used for the surface treatment of polymer materials. Through the chemical reaction between the plasma and the surface of the material, hydrophilic groups such as carbon, carboxyl, and hydroxyl groups are formed, which improves the adhesion, hydrophilicity, and adhesion of materials.

2. Plasma surface cleaning

Taking the mobile phone motherboard in the precision electronics industry as an example, the motherboard is mainly made of conductive copper foil, epoxy resin and glue. If the motherboard needs to be connected to the circuit, it is necessary to drill holes on the motherboard first to form tiny holes. Fine holes are used to connect circuits. There will be some residual glue residue in the tiny holes after drilling. These glue residues will directly cause the copper plating to peel off. Even if the copper plating does not peel off, it will be used in the subsequent use. During the process, a short circuit occurs due to residual glue, and the temperature rises to cause peeling, so it is very necessary to completely remove these glue residues in the micropores. Ordinary water-based cleaning equipment on the market cannot completely remove the glue residue. To completely remove the glue residue, it is necessary to use plasma surface cleaning.

Plasma surface cleaning can be understood as a cleaning process. Different from our daily laundry washing, it is a dry cleaning method, which mainly removes some nano-scale organic pollutants and some invisible particles. The working principle is that the plasma reacts with the pollutants on the surface of the workpiece, and the volatile substances produced are taken away to form an ultra-clean workpiece surface.

3. Detect the effect after plasma activation and cleaning surface treatment

The hydrophilic surface is transformed into a hydrophobic surface by a suitable plasma process or by a suitable coating in the plasma process (with a hydrophilic coating, the opposite effect is obtained). The contact angle test refers to the angle formed by the tangent between the droplet profile and the solid surface at the intersection of three phases when observing the projection of the stationary droplet on the solid. According to the physical definition, a surface with a contact angle less than 90° is hydrophilic (wettable), and a surface with a contact angle greater than 90° is hydrophobic (non-wettable). With plasma surface treatment, the contact angle is changed (larger or smaller).

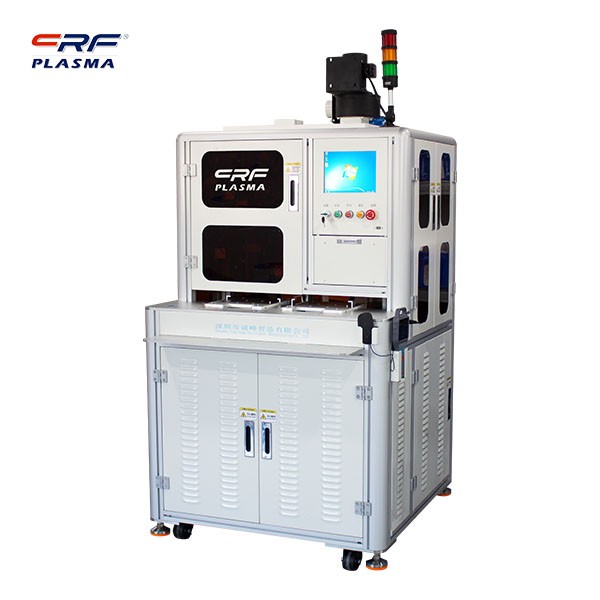

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

Plasma surface treatment Plasma activation cleaning application and effect detection

more >Socket mobile phone panel plasma cleaning machine surface activation cleaning treatment

more >New O2CF4 plasma treatment technology for cleaning the drilling stains of rigid-flex printed circuit boards

more >Photocatalytic material composed of plasma noble metal nanoparticles and semiconductor materials

more >Semiconductor pcb plasma cleaning equipment can be used for various appearance PCB circuit board application processing

more >Design and research of high frequency and high voltage plasma generator

more >