Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

The extended resistance test can indirectly reflect the degree of damage to the substrate surface. The expansion resistance test for lattice damage of the surface layer of a silicon wafer is very effective. The damaged and distorted lattice will increase the expansion resistance value, and its value will have a considerable range of distribution. The greater the plasma energy output at a certain substrate temperature, the faster the removal of silicon dioxide, but at the same time the more serious the lattice damage caused to the silicon surface; insufficient processing time, the silicon surface oxide layer cannot be completely removed. In the case of a certain plasma energy output power, there is a very good processing time range.

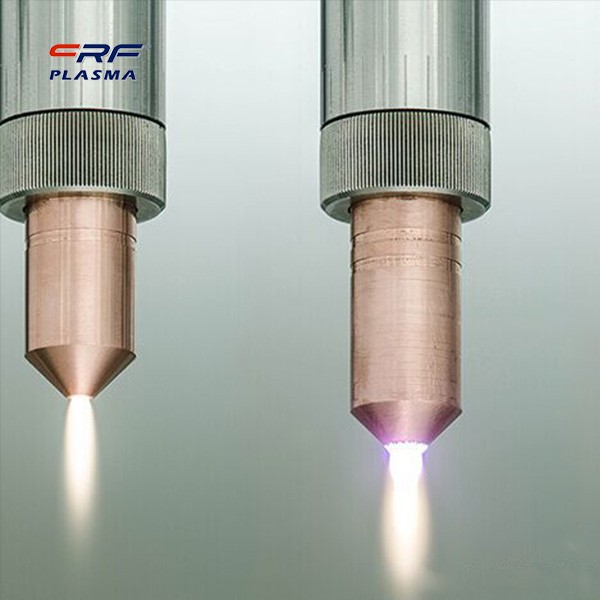

Under the action of low-temperature plasma power and high-frequency electric field, low-pressure hydrogen gas can produce stable self-sustained discharge. The glow discharge produced is a quasi-neutral plasma containing a large number of electrons and ions. When hydrogen molecules are ionized, many possibilities occur. During the collision process, the reaction generates many active groups, which can react with silicon and contaminants on the surface of the substrate. Especially for the contamination of oxygen and carbon, which has a great influence on the integrity of the epitaxial layer, active hydrogen atoms or hydrogen ions can react with them to generate volatile products and be removed.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

Research on the modification effect of various high-energy particles of oxygen plasma on the surface of bamboo charcoal

more >The function and process value of the equipment of Chengfeng Zhizhi plasma processor manufacturer to process masks

more >The NGTi-based TIO2 film becomes very dense, smooth and hydrophilic after the etching process of the Ar plasma cleaner

more >The plasma cleaner manufacturer introduces the difference between magnetic binding fusion and inertial binding plasma

more >Plasma PCB cleaning machine PCB faces greater challenges in materials and process technology

more >The improvement of low-temperature plasma surface treatment machine on the surface bonding effect of PTFE materials

more >