Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

The timeliness of the circuit board processing process of the vacuum plasma cleaning machine:

The process, time and treatment plan of circuit board processing with vacuum plasma cleaning machine can save cost. The surface is raised by radio frequency power under a certain pressure to produce high-energy plasma, and then plasma bombardment is performed on the surface to produce microscopic images. Peeling effect.

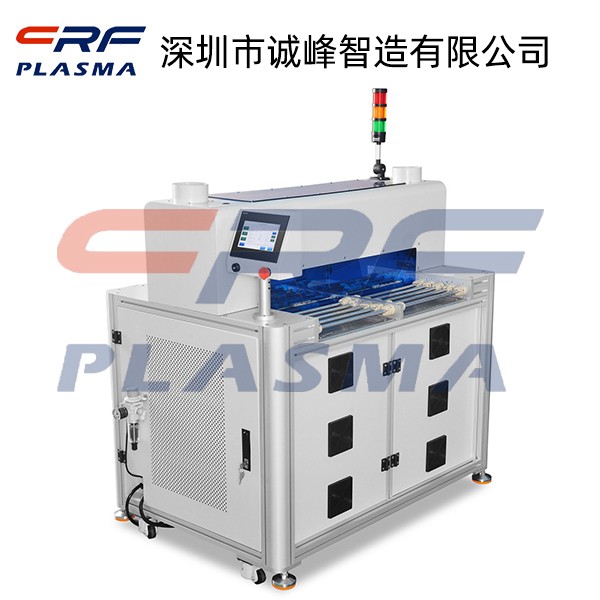

Vacuum plasma cleaning machine

Plasma is used to clean the surface of the circuit board (FPC/PCB) before pre-bonding. Under normal circumstances, downstream customers of circuit boards will carry out incoming material inspections, such as wire bonding inspection, tensile inspection, etc., and when the surface of the product is not cleaned, there will often be some pollution, resulting in unqualified inspections. In order to avoid the above problems, surface plasma cleaning before welding and wire bonding has become a trend in this era of pursuit of high quality.

Use radio frequency power to generate high-energy plasma in the vacuum chamber of vacuum plasma cleaner under certain pressure, and then use plasma to bombard the processed surface to produce microscopic peeling effect (adjusting the plasma bombardment time to adjust the peeling depth, the effect of plasma It is nanometer level, so it will not damage the processed object), so as to achieve the purpose of operation.

Sheet product requirements:

1. Product material: FPC, with yellow glue on the upper part;

2. The dyne value reaches 34↑;

3. The treatment timeliness reaches 1 week↑;

4. Use blister box for pre-shipment treatment, blister box should be free from static electricity and deformation.

The effect of plasma treated circuit board:

1. Dyne value before processing: 32 dyne pens ↓, dyne pens after processing 70 ↑;

2. The contact angle before treatment reaches 80 degrees, and the contact angle reaches 10 degrees after treatment;

3 Processing time: 60S (time can be re-optimized);

4. Gas: oxygen.

Factors affecting product timeliness:

Because the plasma treatment of the vacuum plasma cleaner has the characteristics of chemical and physical changes. Physical and chemical changes mean that the surface of the material is modified and the surface protrusions increase after etching, and the surface area increases. If exposed to contaminated air, mixed with dust, oil, and impurities, the surface energy will gradually decrease. During plasma treatment, chemical changes will introduce oxygen-containing polar groups, such as hydroxyl groups, carboxyl groups, etc. These active molecules are time-sensitive and easy to undergo chemical changes with other substances. It is difficult to determine the retention time of surface energy after treatment. Factors such as gas, power, processing time, and placement environment have an impact on the timeliness of the material surface. The verification time after cleaning the FPC product is: 1 week (confirmed by the contact angle measurement data, the smaller the contact angle value, the higher the dyne value)

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >The packaging screen printing plasma cleaning machine completely solves the problem of packaging screen printing falling

more >Plasma cleaning machine surface modification PCB board plasma cleaning machine

more >Plasma surface activation cleaning technology COG process for mounting bare chip IC on glass substrate (LCD)

more >The introduction of various oxygen-containing groups during plasma treatment makes the surface of the material easy to b

more >