Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

Research on the surface energy and adhesion of polyester monofilament after plasma cleaning:

Polyester monofilament is widely used as a reinforcing material for rubber in automobile tires due to its excellent properties such as high strength, high modulus, and high elasticity. The adhesion between the polyester monofilament and the rubber interface is mainly to use the adhesive to adhere to the two adherends. The wetting performance between the adhesive and the adherend is the main factor affecting the adhesion strength. Good wetting performance can be increased The adhesion performance between the two phases is conducive to the improvement of adhesion strength.

Due to the dense structure, the lack of polar groups on the surface, and the low surface energy of polyester monofilaments, the adhesive is not easy to spread and wet on its surface, so the adhesion to rubber is poor. Plasma cleaning plasma treatment can effectively improve the wetting and adhesion properties of the polymer material surface.

The contact angle can directly reflect the wetting performance of the polyester monofilament surface. The contact angle of the polyester monofilament becomes smaller after plasma treatment, which indicates that plasma cleaning plasma treatment can effectively improve the wetting performance of the polyester monofilament surface. After plasma treatment, an oxidation reaction occurred on the surface, and a large number of polar groups such as carbonyl and carboxyl groups were introduced to the surface of the sample.

Plasma plasma cleaning After plasma treatment, the oxygen element mass fraction on the sample surface increases relatively and the carbon element mass fraction relatively decreases. With the further extension of the treatment time, the etching effect of plasma will remove some polar groups from the sample surface, thereby This results in a slight decrease in the atomic ratio of OC, which is also the reason why the surface energy of the sample decreases after a certain period of time during plasma treatment.

After the polyester monofilament is plasma treated, the surface energy is greatly increased. The change law of plasma treatment time with plasma cleaning is basically consistent with the change law of surface energy over time. This result shows that the polar force component is the main factor that affects the change of the surface energy. The increase of the polar force component enhances the orientation force between polar molecules and the inductive force between polar molecules and non-polar molecules on the interface. The ester monofilament has high enough surface energy to overcome the surface tension of the adhesive and make it easier for the adhesive to spread and wet on the surface of the polyester monofilament. This effect can effectively improve the adhesion performance of the surface of the polyester monofilament.

The law of adhesion strength changing with processing time is basically the same as that of surface energy. Therefore, the adhesion performance of the system can be predicted by measuring the surface energy of polyester monofilaments. Plasma cleaning Plasma treatment introduces a large number of oxygen-containing polar groups on the surface of the polyester monofilament, which increases its surface energy and wettability, thereby improving the adhesion between the polyester monofilament and the rubber.

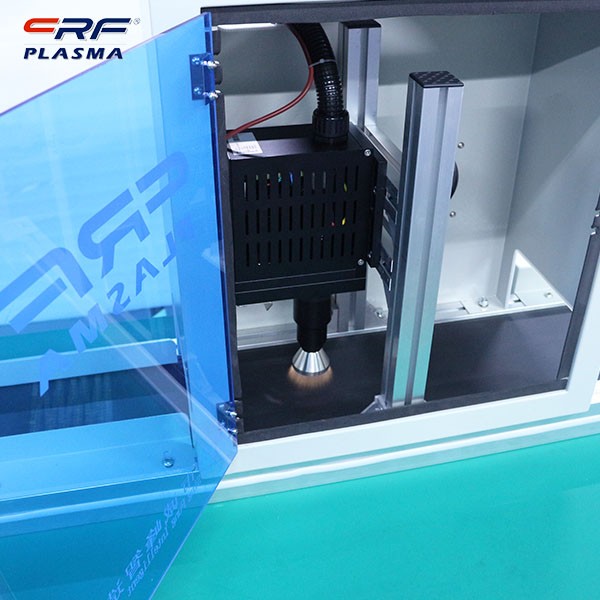

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >The packaging screen printing plasma cleaning machine completely solves the problem of packaging screen printing falling

more >Plasma cleaning machine surface modification PCB board plasma cleaning machine

more >Plasma surface activation cleaning technology COG process for mounting bare chip IC on glass substrate (LCD)

more >The introduction of various oxygen-containing groups during plasma treatment makes the surface of the material easy to b

more >