Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

CRF-APO-RP1020-D

13632675935

Contact now

|

Name |

Jet type AP plasma processing system |

|

Plasma power supply model |

CRF-APO-RP1020-D |

|

Rotary spray type plasma spray gun model |

Rotary spray type: RXX (Option: 20mm-80mm)RXX(Option:20mm-80mm) |

|

Power supply |

220V/AC,50/60Hz |

|

Power |

600-1000W/25KHz(Option) |

|

Power factor |

0.98 |

|

Processing height |

5-15mm |

|

Handling wide format |

Rotary jet type:20-80mm(Option) |

|

Internal control mode |

Digital control |

|

External control mode |

RS485/RS232、analog communication port, start-stop I/O |

|

Working gas |

Compressed Air (0.4mpa)/N2(0.2mpa) |

|

Power supply weight |

10kg |

Use plasma surface treatment of electronic components and chips to make them more refined and clean

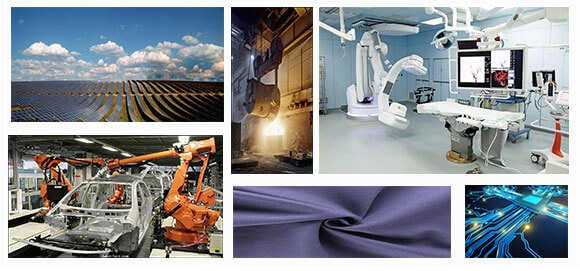

In the production process of electronic components, auto parts and other industrial components due to cross-contamination, natural oxidation, flux, etc., various contaminants will be formed on the surface. These contaminants will affect the welding, bonding and other related processes of the components in the subsequent production. Quality, reduce the reliability and pass rate of finished products. Plasma treatment processes the surface of the workpiece through chemical or physical action. The ionization of the reactive gas generates highly active reactive ions, which chemically react with surface contaminants for cleaning. The reaction gas needs to be selected according to the chemical composition of the pollutant. The chemical reaction-based plasma cleaning has a fast speed, good selectivity, and a good cleaning effect on organic pollutants. Plasma cleaning where the surface reaction is based on physical action is very commonly used to use argon gas, which does not produce oxidation by-products, and the etching effect is anisotropic. Generally, in the plasma surface modification process, chemical reactions and physical effects co-exist, resulting in better selectivity, uniformity and directionality.Due to the development direction of precision and miniaturization in the industrial field, plasma surface modification technology will have more and more important applications in the semiconductor industry, chip industry, aerospace and other high-tech industries with its advantages of fine, clean, and non-destructive modification. value. The semiconductor packaging industry, including the packaging of integrated circuits, discrete devices, sensors and optoelectronics, usually uses copper lead frames. In order to improve the reliability of bonding and encapsulation, copper brackets are generally put through a plasma cleaning machine for a few minutes Treatment to remove organic matter and contaminants on the surface and increase the solderability and adhesion of the surface.

Top 500 enterprises choose brands for a long time

20 years of independent R & D experience in top 500 enterprises, a number of technology patent certification.

Adopt imported components through EU CE certification so that you can use them without worry.

Professional R & D team

Has a number of assembly engineers who have been engaged in the industry for more than ten years.

Advanced equipment

Certification treats every equipment test

Strict quality control

The equipment runs and debugs continuously for 24 hours before coming out.

Perfect service system

A high-tech enterprise integrating R & D, manufacturing, production and sales of plasma equipment.

The service industry has a wide range of fields.

Focus on plasma research and development for 20 years, serving a variety of industries

Special customizable equipment

Make the equipment completely according to the customer's requirements.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >The effect of the oxidizing gas N2 on the conversion reaction under the action of plasma

more >Research on the modification effect of various high-energy particles of oxygen plasma on the surface of bamboo charcoal

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >Plasma surface treatment Plasma activation cleaning application and effect detection

more >The function and process value of the equipment of Chengfeng Zhizhi plasma processor manufacturer to process masks

more >