Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

CRF-APO-500W-XN

13632675935

Contact now

Name

Fully automatic On-Line AP plasma processing syste

Model

CRF-APO-500W-XN

Power supply

380V/AC,50/60Hz

Plasma power

10KW(Max)/ 40KHz(Option)

Effective processing height

3-8mm(MAX)

Effective processing width

120-1200mm(Option)

Processing speed

0-8m/min

Working gas

N2/N2+CDA

Fully automatic plasma treatment system plasma cleaning machine manufacturer specific application of plasma cleaning technology

1. High aspect ratio double-layer flexible board to remove slag, hard-soft fusion board to remove slag to improve the bonding compressive strength between the hole edge and the copper plating layer, remove the slag to improve reliability, and avoid the inner layer after copper plating Cause an open circuit.After the plasma surface treatment machine, whether it is a variety of polymer plastics, ceramics, glass, PVC, paper or metals, they can get better surface energy. Using this treatment process can improve the surface tension performance of the product, which is more in line with the industrial requirements for coating, bonding and other treatments.

Top 500 enterprises choose brands for a long time

20 years of independent R & D experience in top 500 enterprises, a number of technology patent certification.

Adopt imported components through EU CE certification so that you can use them without worry.

Professional R & D team

Has a number of assembly engineers who have been engaged in the industry for more than ten years.

Advanced equipment

Certification treats every equipment test

Strict quality control

The equipment runs and debugs continuously for 24 hours before coming out.

Perfect service system

A high-tech enterprise integrating R & D, manufacturing, production and sales of plasma equipment.

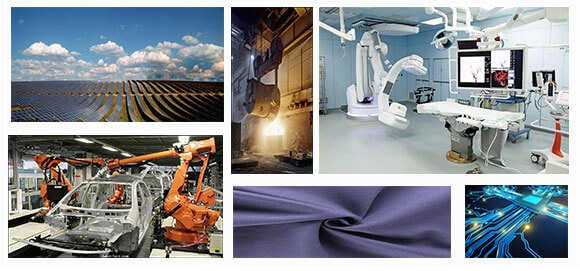

The service industry has a wide range of fields.

Focus on plasma research and development for 20 years, serving a variety of industries

Special customizable equipment

Make the equipment completely according to the customer's requirements.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >The effect of the oxidizing gas N2 on the conversion reaction under the action of plasma

more >Research on the modification effect of various high-energy particles of oxygen plasma on the surface of bamboo charcoal

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >Plasma surface treatment Plasma activation cleaning application and effect detection

more >The function and process value of the equipment of Chengfeng Zhizhi plasma processor manufacturer to process masks

more >