Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

CRF-APO-RP1020-D

13632675935

Contact now

|

Name |

Jet type AP plasma processing system |

|

Plasma power supply model |

CRF-APO-RP1020-D |

|

Rotary spray type plasma spray gun model |

Rotary spray type:RXX(Option:20mm-80mm) |

|

Power supply |

220V/AC,50/60Hz |

|

Power |

600-1000W/25KHz(Option) |

|

Power factor |

0.98 |

|

Processing height |

5-15mm |

|

Handling wide format Rotary jet type: |

旋噴式:20-80mm(Option) |

|

Internal control mode |

Digital control |

|

External control mode |

RS485/RS232、analog communication port, start-stop I/O |

|

Working gas |

Compressed Air (0.4mpa)/N2(0.2mpa) |

|

電源重量 |

10kg |

Scope of application

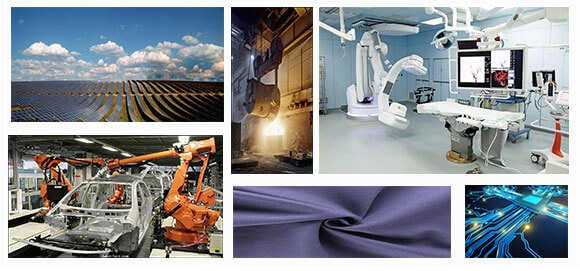

Plasma cleaning machine Plasma treatment instrument is mainly used in the pre-processing of mobile phone shell printing, coating, dispensing, etc. in the electronics industry, surface treatment of mobile phone screens; surface cleaning of connectors; screen printing and transfer printing pre-processing in general industries.

Plasma cleaning is the only way to improve product yield. Flip chip machines are becoming more and more attractive in the market. Plasma technology has an incomparable advantage in penetrating the fine voids of the mold. The surface layer can be activated and activated regardless of the size of the object.

The plasma treatment system can provide rapid and well-proportioned cleaning or stripping effects. The cleaning process of the plasma processor is heated by a higher concentration of free radicals and a low-density plasma. Good uniformity, good control of the processing technology and operation of the actual operation on a single substrate are very critical.

1. Plasma cleaning and activation before packaging

The cleaning activity technology of the plasma processor has a significant improvement effect on the improvement of the bonding characteristics of the package mold in the semiconductor material micro integrated circuit chip. Highly active plasma uses the organic chemical kinetic energy of free radicals to process various substrate surfaces: solder mask materials, mold passivation treatment layers, pads and lead frame surfaces. This eliminates the problem of mold delamination, and according to the application of polyvinyl alcohol plasma, there is no electrostatic induction discharge or other potentially harmful adverse reactions.

2. Plasma etching package

De-encapsulation of packaged components such as integrated circuit chip IC and printed circuit board pcb makes the internal components exposed. Opening the decapsulation equipment can check the mold, connection and its characteristics in the process of common fault analysis. The selective etching of the polymer packaging material is the key basis for component failure analysis, and does not harm the consistency of the metal wire and the component layer. Plasma cleaning is used to clean and remove packaging materials. Plasma etching has high selectivity and will not be affected by the plasma etching process.

3. Plasma cleaning before welding

Plasma processor cleaning is an important process for improving the cleanliness of pads in integrated circuit chips. After plasma cleaning treatment, the shear strength and tensile strength of the ball are obviously enhanced. Ideally, during the tensile test, when the wire breaks in the span, it should be maintained electrically welded to the bonding pad. PVAtepla's distinctive plasma can effectively remove organic pollutants and metal oxides.

Plasma cleaning machine cleaning is also applicable to the processing of touch screens. For example, before connecting and bonding, the liquid crystal display or OLED terminal is removed from the organic contaminants at the connection, and then it is fused with the conductive film. In addition, in the integrated IC installation (COG) pretreatment, the plasma activation of the glass is another key application.

Application of Plasma Cleaner in FPC Circuit Board Industry

As the substrate of electronic components, printed circuit boards are conductive, which poses a challenge to the use of atmospheric pressure process to process printed circuit boards. Any surface pretreatment method, even if only a small potential is generated, may also cause short circuits, leading to wiring and electronic devices damage. For this type of electronic applications, the special performance of plasma cleaner processing technology provides new possibilities for industrial applications in this field.

Application of plasma cleaning machine in silicon wafer and chip industry

Silicon wafers, chips, and high-performance semiconductors are extremely sensitive electronic components. As a manufacturing process, plasma cleaner technology has also developed with the development of these technologies. The development of plasma technology in the atmospheric environment provides a new application prospect for plasma cleaning, especially in fully automatic production.

Top 500 enterprises choose brands for a long time

20 years of independent R & D experience in top 500 enterprises, a number of technology patent certification.

Adopt imported components through EU CE certification so that you can use them without worry.

Professional R & D team

Has a number of assembly engineers who have been engaged in the industry for more than ten years.

Advanced equipment

Certification treats every equipment test

Strict quality control

The equipment runs and debugs continuously for 24 hours before coming out.

Perfect service system

A high-tech enterprise integrating R & D, manufacturing, production and sales of plasma equipment.

The service industry has a wide range of fields.

Focus on plasma research and development for 20 years, serving a variety of industries

Special customizable equipment

Make the equipment completely according to the customer's requirements.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >The effect of the oxidizing gas N2 on the conversion reaction under the action of plasma

more >Research on the modification effect of various high-energy particles of oxygen plasma on the surface of bamboo charcoal

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >Plasma surface treatment Plasma activation cleaning application and effect detection

more >The function and process value of the equipment of Chengfeng Zhizhi plasma processor manufacturer to process masks

more >