Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

The advantages of vacuum plasma cleaning system:

The plasma cleaner system made of high-quality alumina and ceramics has excellent durability. The low-cost reactive ion etching system and anisotropic reactive ion etching can complete cleaning and activation independently.

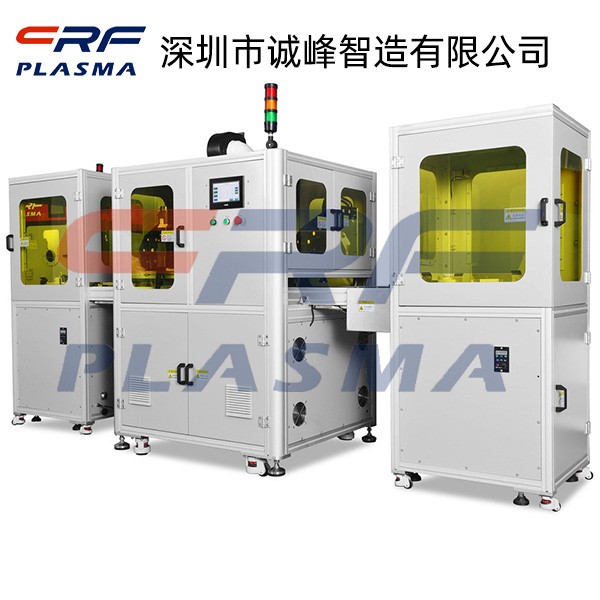

Vacuum plasma cleaning system

In addition, the vacuum plasma cleaning system chassis can also be used as an integrated safety enclosure to accommodate the plasma chamber, control electronics, 13.56MHz radio frequency generator and automatic matching network (only vacuum pump outside the system). Provide maintenance access through interlockable doors or detachable panels.

The vacuum plasma cleaning system made of high-quality alumina anode materials and ceramic materials has excellent durability. The plasma chamber can be equipped with "6" or "8" power electrodes or even more to adapt to various wafer sizes, parts, IC packages and other components.

High-performance plasma etching is used for failure analysis or MEM and LED device manufacturing. The vacuum plasma cleaning system is suitable for various process gases, including: Ar, O2, H2/forming gas, He, CF4 and SF6.

Features and advantages of vacuum plasma cleaner system cleaning and live processing:

(1) Touch screen control and graphical user interface provide real-time process data and feedback.

(2) The 13.56MHz RF generator and automatic matching network are used to provide the repeatability of the production process.

(3) The temperature control loop integrated in the plasma chamber is controllable.

The plasma confinement ring focuses the plasma directly on the wafer to accelerate etching, provide uniform plasma coverage, and isolate the plasma from the wafer itself rather than from the surrounding area. Because of the ability to increase the etching rate, there is no need to increase the electrode temperature or increase the bias of the chuck. This ring is made of insulating non-conductive material, and the conductive path between aluminum plasma and aluminum is limited to the wafer area. There is a gap of 2mm between the toroidal tape and the frame piece. Because there is no plasma generation or at the bottom of the wafer and tape, undercuts and delamination are minimized, and there will be no sputtering or tape deposition on the wafer surface. The plasma etching system is designed for advanced etching applications, such as: dielectric materials that can be used for packaging, removing oxides, nitrides, polyimides, silicon, metals, ILEDs or IC devices, and removing epoxy resins Interlayer film, used to remove photoresist.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >The packaging screen printing plasma cleaning machine completely solves the problem of packaging screen printing falling

more >Plasma cleaning machine surface modification PCB board plasma cleaning machine

more >Plasma surface activation cleaning technology COG process for mounting bare chip IC on glass substrate (LCD)

more >The introduction of various oxygen-containing groups during plasma treatment makes the surface of the material easy to b

more >