Support material testing and equipment testing

Focus on R & D and manufacturer of plasma cleaning machine for 20 years

The automatic vacuum plasma cleaning machine supports manual and automatic operation. The volume of the plasma cleaning machine and the short cycle achieved by the proprietary plasma process control can be achieved within a few seconds to increase the power of the chamber to meet the requirements of processing products by using a proprietary R&D system.

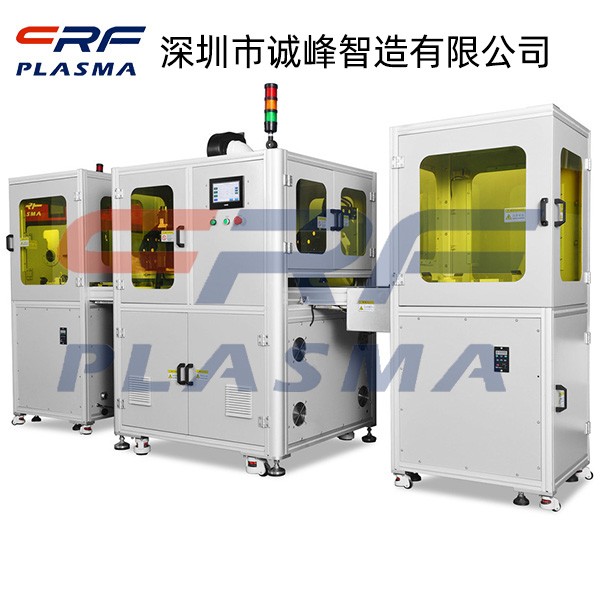

Automatic vacuum plasma cleaning machine

The automatic vacuum plasma cleaning machine supports manual and automatic operation (built-in processing program). The particularly uniform and compact cavity design allows interchangeable processing structures and plasma modes. The three-axis symmetrical plasma chamber ensures that the product can be uniform in all positions At the same time, all process parameters are strictly controlled to ensure that the product can be reused.

At the same time, its compact structure greatly reduces the need for space. The general structure can handle a variety of product form factors, including FPC, PCD, carrier, strip, laminate and chip. The automatic vacuum plasma cleaner system can be configured into single and multiple ribbon or ribbon frames, wafer processing, depending on the requirements of output and product form. The system can automatically restore the plasma ready state, compensate for vacuum pressure, temperature changes and different batch sizes. Using a special technology, high power can be achieved in a few seconds, and the forward and reflected power of the cavity can be continuously measured.

Features and advantages of automatic vacuum plasma cleaning machine:

1. It is easy to integrate various process equipment, including wire welding, patch, batching, mold and marking.

2. Independent structure, it occupies a small space.

3. Compact three-axis symmetry room and proprietary process control.

4. The processing speed is fast, the application range is wide, and the processing cycle is short.

The plasma processing system conforms to the standard configuration of advanced semiconductor and electronic packaging plasma cleaning and processing. The large-scale plasma system is specially designed for processing large-scale substrates. It has a high-capacity plasma chamber, which is 235 liters, several times the standard capacity.

CRF-VPO-4L-S

CRF -APO-IP-XXHD-DXX

CRF-APO-500W-C

CRF-APO-IP-XXHD-RXX

CRF-APO-RP1020-D

CRF-VPO-8L-M

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying

more >Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

more >The packaging screen printing plasma cleaning machine completely solves the problem of packaging screen printing falling

more >Plasma cleaning machine surface modification PCB board plasma cleaning machine

more >Plasma surface activation cleaning technology COG process for mounting bare chip IC on glass substrate (LCD)

more >The introduction of various oxygen-containing groups during plasma treatment makes the surface of the material easy to b

more >